DAYSON

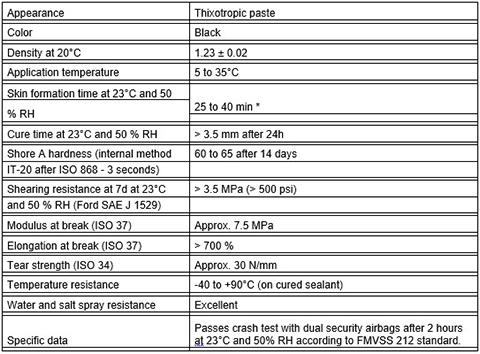

WINDSHIELD SEALANT

*This time depends on hygrometry and ambient temperature. In order to ensure a good adhesion, it is mandatory to do the bonding before the product has formed its skin.

The substrates to be bonded must be even, dry, dust free and not have any traces of grease or other contaminants that could harm bonding (silicones or demoulding agents for example). In case of a windshield replacement, it is not necessary to completely remove the old sealant: simply trim it off, leaving a 1 to 2 mm thickness. There is no compatibility problem applying fresh polyurethane sealant on old polyurethane sealant. Rub down any rusted area. Bare areas of the body must be cleaned with acetone or heptane before applying PRIMER WS. Note: when using solvents, extinguish all sources of ignition and carefully follow the safety and handling instructions given by the manufacturer.

Depending on the type of windshield, it must be treated as follows:

RAW GLASS :DAYSON WINDSHIELD recommendations: Activator ACTIVATOR / Black primer PRIMER WS / Windshield sealant

Clean with ACTIVATOR according to the “WOWO” method (“Wipe On - Wipe Off”) with a clean, dry and lint-free cloth (wipe as soon as the solvent is evaporated, i.e. 30 to 60 seconds after application). Close immediately the bottle after use, as this product is very sensitive to humidity. If it became cloudy, do not use it anymore. For this application, it is possible to use single-use impregnated wipes (kit containing an impregnated wipe and a dry one for “WOWO”). Respect a drying time of 10 to 60 minutes depending on the temperature.In case this drying time would be exceeded, renew the operation. Then apply a thin and uniform layer of PRIMER WS with an applicator pad (or a 10 ml tube with single-use foam sponge applicator) in order to form a homogeneous film.

Well homogenize the primer before application:

- if packed in bottle: shake it thoroughly until agitator ball is moving then shake another 30 seconds,

- if packed in 10 ml tube: shake it thoroughly for 10 to 15 seconds.

Close the bottle immediately after use. Any contact of the primer with humidity will cause its curing. For this reason, the product must be used within 24 hours which follow the opening of the bottle. Respect a drying time of 15 to 60 minutes depending on temperature before applying the sealant.In case this time would be exceeded, the sealant’s application can be done within 24 hours maximum, on the condition that there is no dust or traces of possible contaminants (grease or silicone).

WINDSHIELD WITH CERAMIC FRIT :DAYSON instructions : Anti-silicone treatment / Activator / (Black primer / Windshield sealant Bonding may be performed with or without primer.

Cleaning:DAYSON WINDSHIELD recommendations: Anti-silicone treatment / Activator ACTIVATOR / (Black primer PRIMER WS) / Windshield sealant Bonding can be performed with or without the use of primer.Bonding without PRIMER WS must be performed on a windshield with a ceramic frit ensuring optimal and uniform opacity to UV and not presenting silicone residues. Failure to respect these two conditions can cause a partial or total loss of adhesion of the sealant on the windshield. To eliminate silicone residues, degrease with heptane or methylethylketone (MEK), then abrade with “3M Scotch-Brite Red” (to overcome the “orange peel effect” likely to occur in presence of silicone residues). Degrease a second time with heptane or methylethylketone (MEK) and respect a drying time of 10 minutes according to temperature of the workshop. Apply ACTIVATOR according to the method described for raw glass.

Respect a drying time of 10 to 60 minutes before next step:

- if the ceramic frit is sufficiently opaque: apply the sealant

- if the ceramic frit is not sufficiently opaque: apply PRIMER WS with an applicator pad (or a 10 ml tube with single-use foam sponge applicator), respect a waiting time of 15 to 60 minutes before applying the sealant.

-ENCAPSULATED WINDSHIELD: Degrease if needed with methylethylketone (MEK) or acetone, respect a drying time of 10 minutes and then apply EMFIPRIM 34025A *.

WINDSHIELD COATED WITH A PRIMER: degrease with MEK or acetone. After about 10 minutes, apply DAYSON FAST WINDSHIELD *

Degrease with methylethylketone (MEK) or acetone, respect a drying time of 10 minutes and then apply DAYSON WINDSHIELD *.

* follow the same instructions for use as those indicated above for the application of PRIMER WS packed in bottle.

Caulking:Dayson Windshield can be applied by a manual or pneumatic gun.

The triangle-shaped form of the joint is determined by the shape of the nozzle.

The windshield must be applied and pressed before the product has formed its skin.

Note: all the durations given in the instructions for use above are valid for a minimal temperature of 15°C. For lower temperatures (between 5 and 15°C), twice longer drying times must be respected.

Read material safety data sheet before use.

The technical data contained herein is based on our present knowledge and experience and we cannot be held liable for any errors, inaccuracies, omissions or editorial failings that result from technological changes or research between the date of issue of this document and the date the product is acquired.

Before using the product, the user should carry out any necessary tests in order to ensure that the product is suitable for the intended application. Moreover, all users should contact the seller or the manufacturer of the product for additional technical information concerning its use if they think that the information in their possession needs to be clarified in any way, whether for normal use or a specific application of our product.

Our guarantee applies within the context of the statutory regulations and provisions in force, current professional standards and in accordance with the stipulations set out in our general sales conditions.

The information detailed in the present technical data sheet is given by way of indication and is not exhaustive. The same applies to any information provided verbally by telephone to any prospective or existing customer.